In 1986, I paid an electrician buddy of mine $800 to convert a 110 volt Microfiche reader to operate on the 12 volt automotive electrical system. I thought I was a genius! I then put the converted reader in the back of our parts delivery van so we could look up parts at the customer’s location.

At first I got laughed at, but that year we increased our wholesale parts sales by $575,000. Not bad for 1986 money.

At first I got laughed at, but that year we increased our wholesale parts sales by $575,000. Not bad for 1986 money.

It’s funny but there always seems to be some accidental consequences of technology. Along with over half a million dollars in new sales, we started to notice that our returns were fewer, especially when tracked against wholesale orders.

Lower returns started to have a positive effect on our parts inventory and slowly the dollar figure for obsolete parts moved in the right direction.

Then another thing we never expected happened. We started to have insurance adjusters asking us to meet them on site as a sort of mobile parts catalog to help with their vehicle inspection. Having that catalog data available at the time of writing the estimate apparently led to fewer supplemental orders to their estimates. It soon became routine to be called by either the collision shop and/or the insurance adjuster and invited onsite with our portable parts catalog. Whenever they had to iron out the cost of fixing a wreck, it helped to have the catalog data at their fingertips.

That 12 volt Microfiche reader made us an indispensable part of the team. Since I paid my mortgage and fed my kids on money made from selling parts, I was quite happy to be part of that team. I not only gained new customers, I kept my old ones satisfied by simplifying their parts ordering business.

I have always believed that anytime you can make a complicated task easier to do, the more people are willing to do it, and the more people that are affected by this simplification, the greater the effect.

So what does that have to do with the Parts business today? Granted, I didn’t patent the converted Microfiche reader and launch a fleet of microfiche-loaded parts vans. But, an easier, more accurate method was found to identify parts.

This month, we are pleased to have a guest contributor, Mr. Jack Steinkamp. A Fixed Operations consultant with over 40 years of Service and Parts experience, Jack currently advises automotive suppliers on the design and function of EPC, MPI, and Service Menu pricing programs. He also conducts informative and relevant webinars on new products and services available to parts and service departments.

As years went by, microfiche was replaced by data processers, desktop computers, and laptops. Sure, parts catalogs were now electronic, but they were still limited. How did you know if a part was obsolete, superseded, recalled, or which supplemental parts were often replaced with it?

As computers became more prevalent and affordable, the market was flooded with electronic parts catalogs, promising more accurate orders, shorter cycle times, and increased convenience. But when inspected more closely, a lot of these EPCs were electronic copies of the printed manual that required regular computer or server downtime for system updates. Although a step in the right direction, Parts interpreters were still waiting on the latest information.

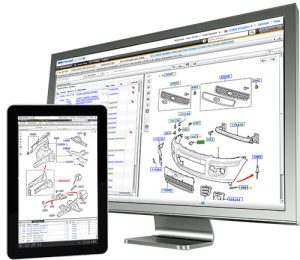

All that changed with the launch of Microcat. The best EPC on the market makes your job easier and provides constantly updated data; no servers, no discs, or dongles. All genuine parts data is stored in the cloud and ready when and wherever you are.

The data in Microcat is updated automatically whenever the manufacturer makes changes – on a weekly if not more frequent basis. Most important, it requires no effort on the part of the user. All changes occur “in the cloud.” Anyone using a disc based catalog knows the data is always 30-60 days old, resulting in parts prices, supersessions, and data that often lead to countless “invisible” mistakes every year.

Microcat’s online architecture also takes all the complication out of sharing things like notes, orders and VIN Tags between users. The minute user “A” enters a note, users “B, C, D & E” all see the note, regardless of their location.

Microcat’s online architecture also takes all the complication out of sharing things like notes, orders and VIN Tags between users. The minute user “A” enters a note, users “B, C, D & E” all see the note, regardless of their location.

Microcat LIVE also frees its users up to do business from outside the confines of the dealership. An order can be looked up and saved at a remote location and instantly picked, pulled, and invoiced back at the dealership. Whether the transaction takes place 100 or 1,000 miles away from the dealership, the second the “save” button is clicked, the order is visible to everyone logged into Microcat.

I’m not quite done yet. This intelligently designed EPC isn’t restricted to only catalog users. Microcat LIVE enables you to easily share information with your customers. A single click will allow a user to print or email a complete VIN breakdown to a customer. Another click will print or email an illustration, and gives you the option of including a complete list of every VIN specific part in that illustration. In effect, you can create a “mini catalog” of any section email to your customer. You can also choose to hide part numbers and/or pricing if you desire.

If TSB’s, Bulletins and/or Installation/fitment guides are part of your OEM data, Microcat enables you to print or email those documents as well.

You might be thinking that you’re going to need a really, really smart computer geek to make all this work. Not so, I have no idea how they did it but “honest and true” you will not have to spend 1 minute setting up Microcat to do ANYTHING I have described in this article. They also have dedicated Customer Service staff available to answer any product questions.

I was almost going to say “It works like this right out of the box.” But, come to think of it, there isn’t even a box; as soon as you go online and access Microcat everything just works!

If you prefer, you can still actually buy a 12 volt Microfiche reader for about $300.00 (Google It).